Technical Specifications

Whether your application is black liquor, tall oil, chemical, chlorine, stock or any other medium, give Indu-Tech a call with your application data. We have probably done it.

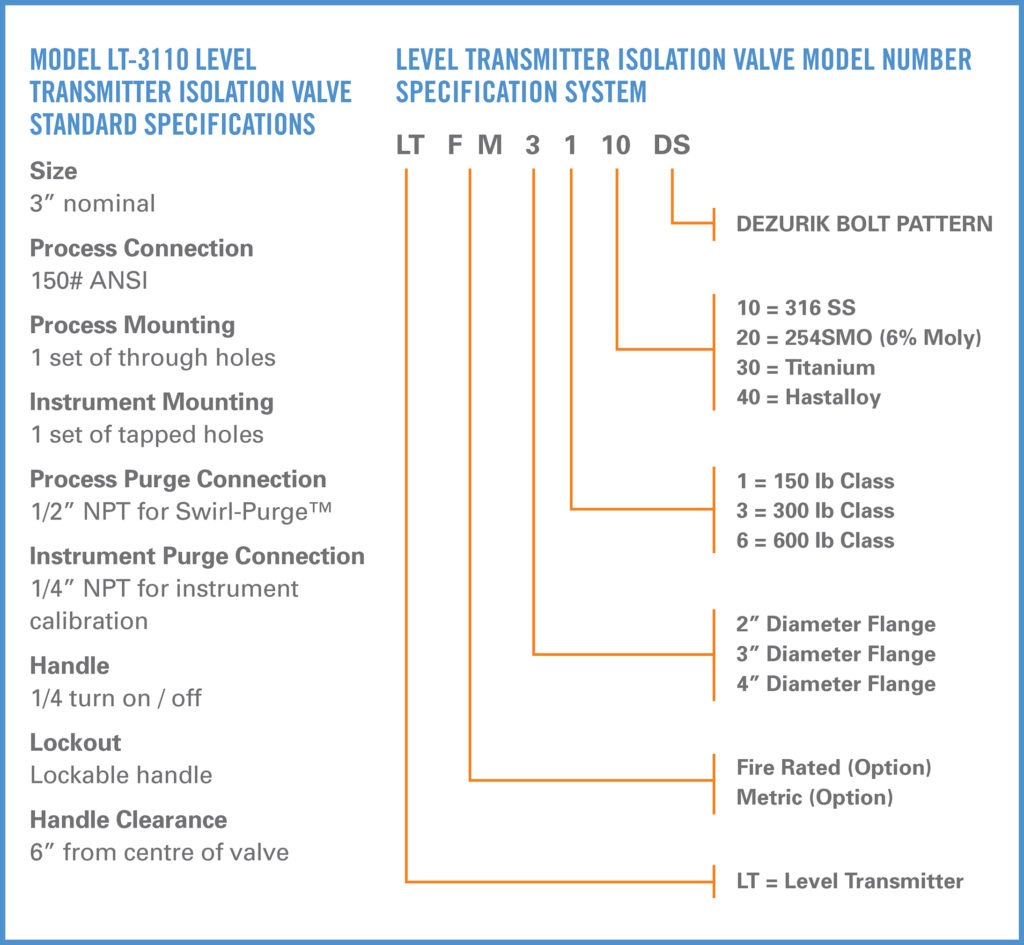

Indu-Tech Isolation Valve Selection Chart

Standard Applications

Valve Model LT 3-inch, 150 lb 316 SS is a standard valve model.

Custom Applications

For unique applications the Indu-Tech valve is available in:

Diameter Flange Sizes 2-inch, 3-inch, 4-inch

Pressure Ratings

- 150 lb Class

- 300 lb Class

- 600 lb Class

Specialty Materials

The Indu-Tech valve is available in a wide variety of materials to suit specific applications.

API 607 Fire Rated

The fire rated Indu-Tech Level Transmitter Isolation Valve is API 607 4th edition certified.

- CRN certified (Canada)

- EPA bubble tight

- ANSI specifications

- API 598

- Metric specifications

- Offset flange for KGV retrofit

- ISO 9003-2015